WE’RE LEADING REFRACTORY SERVICE SPECIALIST IN INTEGRATED STEEL PLANTS

REFRACTORY SERVICES

Steel Ladle

Lining

CONARC Furnace

Lining

Torpedo Ladle

Lining

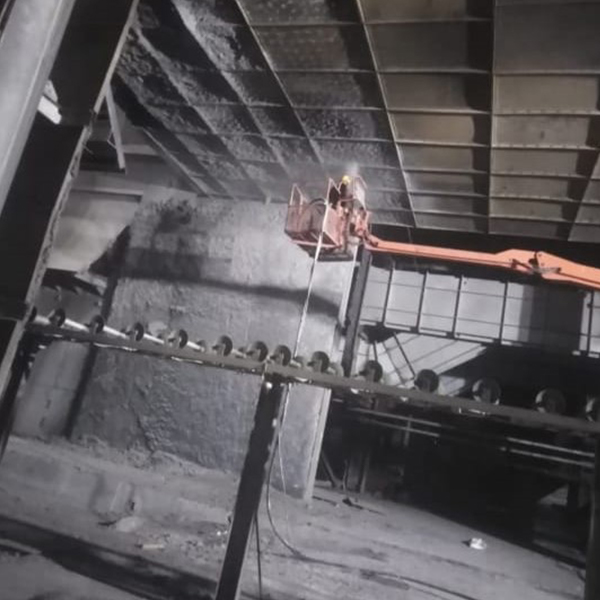

SPONGE

IRON PLANT Gunning

Lime

Calcination Plant Lining

WE HAVE GUNNING JOB EXPERTISE IN

Launder and Slag Door

Metal Jam Cleaning

Miscellaneous

Gunning

Sinter plant

Gunning